|

Features: |

|

|

|

|

| |

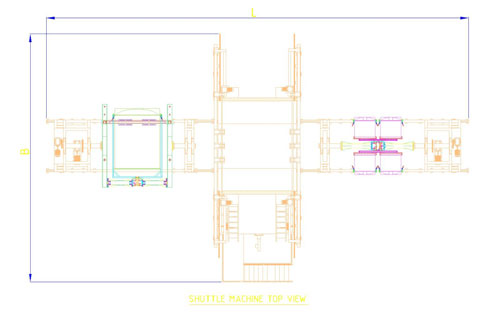

Naroto offers shuttle machines where arms are supported at both side to carry heavy load, instead of cantilever type arms. For smaller capacities cantilever are also offered. Suitable oven chambers are provided with burner and blower for fast heating of moulds to achieve shorter cycle time.

|

|

|

|

Straight arms are designed to carry 12 nos of moulds with three nos of four mould carrier |

|

|

|

High efficiency industrial portable cooling fans are provided for faster cooling of moulds |

|

|

|

There is a manhole at the top of the oven for second/third layer charging |

|

|

|

Control panel is designed with suitable interlocks for safety |

|

|

|

Control panel are of micro processor base with digital display |

|

|

|

A/c variable drives are inbuilt feature for arms major and minor rotation |

|

|

|

Mould and arm positioning for easier charging for second/third layer material |

|

|

|

Wide range of models are available ranging from 1000 ltr to 20000 ltr capacity |

Moving oven with moving carriage [shuttle]

Moving oven with moving carriage [shuttle]